I-Cement Compression & Imishini Yokuhlola Okuguqukayo

- Ukuchazwa Komkhiqizo

I-Cement Compression & Imishini Yokuhlola Okuguqukayo

Ukucindezelwa kosekhulile kanye nomshini ovumayo ngokuhlolwa okubili

-

Uhla olubanzi lwemishini yokuhlola amamitha kanye nodaka esikunikezayo kusivumela ukuthi sihlangabezane nezidingo eziningi. Izinhlobo ezahlukahlukene zamafreyimu zenzelwe ngokukhethekile ukusetshenziswa okuthile:

Onke amafreyimu afakwe idivaysi yokuphepha ephazamisa isivivinyo ngemuva kokuphula ama-specimen ukuvimba izesekeli ezisetshenziswe ngesikhathi kungonakaliswa.

-

Amafreyimu anesilinganiso sokulinganisa esiphindwe kabili: 300 kn ngokuhlolwa kokucindezela kanye ne-10 kn yokuhlolwa kokugoba.

Ukungcola / Ukumelana Nemfumba

Amandla wokuhlola aphezulu: 300kn / 10NK

Izinga lomshini wokuhlola: Izinga 1

Isikhala esicindezelwe: 180mm / 180mm

I-Stroke: 80 mm / 60 mm

Ipuleti elicindezelwe elingaphezulu: φ18mm / φ60mm

Ipuleti yebhola le-ball head upper Pressure: φ170mm / NONA

Ipuleti eliphansi lokucindezela: φ05mm / noyedwa

Usayizi we-MainFrame: 1160 × 500 × 1400 mm;

Amandla womshini: 0.75kw (uwoyela motor motor 0.55 kw);

Isisindo somshini: 540kg

Usayizi wodaka wokuhlolwa kwamandla eziguqukayo

I-Cement Prism Specimen: 40x40x160mm

Isoftware ye-Center Flealfral and Conspive Felt Test Test

-

I-4.1 I-Windows esekelwe esibonakalayo, kulula futhi ishesha ukufinyelela imisebenzi ehlukile, ilungele iningi labasebenzisi lisebenzisa imikhuba.

-

4.2 Isoftware ihlinzeka ngokulawulwa kwe-Multipty Functional Control: Load (stress) control; Ukulawulwa (uStroke) Ukulawula, ukubambana (i-defform (deformation) Ukulawula, ukugcina umthwalo, ukugcina okulawulwa, ukulawulwa kwezinhlelo ezenziwe ngezifiso.

-

I-4.3 kwimodi yokulawula uStroke, opharetha angachaza isivinini sokuhlola esenziwe ngokwezifiso ukuze ahambisane nezinga elihlukile lokuhlola. Isikhundla Semikhawulo esethiwe kanye nesikhundla sokubuya sizovikela ukuphepha futhi sibuyise ngokuzenzakalelayo ngemuva kokuqedwa kokuhlolwa. Emodini yokulawula uhlelo, umshini wokuhlola ulawulwa yizinhlelo ezinemibandela, opharetha ungafaka isimo ngasinye ukulawula inqubo yokuhlola, futhi isoftware ingathola ukulawulwa kwamapharamitha njalo ngalo msebenzi.

-

4.4 Qaphela ukuboniswa kwe-inthanethi okuku-inthanethi nokuzala.

-

4.5 Sondeza noma ukuphuma komdwebo wokuhlola kunoma iyiphi indawo nganoma yisiphi isilinganiso.

-

4.6 I-Auto Suit the DIAGRAM ngokusho kwesinqumo sokubonisa

-

I-4.7 ixhumanisa iphuzu lokulandela ukubheka imiphumela yokuhlola ephuzwini ngalinye

-

4.8 Isoftware ihlinzeka ngendlela ehlukile yokwakha umbiko wokuhlola: Umbiko Wokuhlola Oyedwa, Umbiko Wokuhlola we-Batch, Umbiko Wokuhlola Wezifiso, Umbiko Wokuhlola Amaphoyinti

-

I-4.9 Test Curves: Isikhathi sokulayisha, isikhathi sokunwetshwa, ukukhishwa komthwalo, ukunwetshwa komthwalo, ukucindezela-ukucindezela, njll

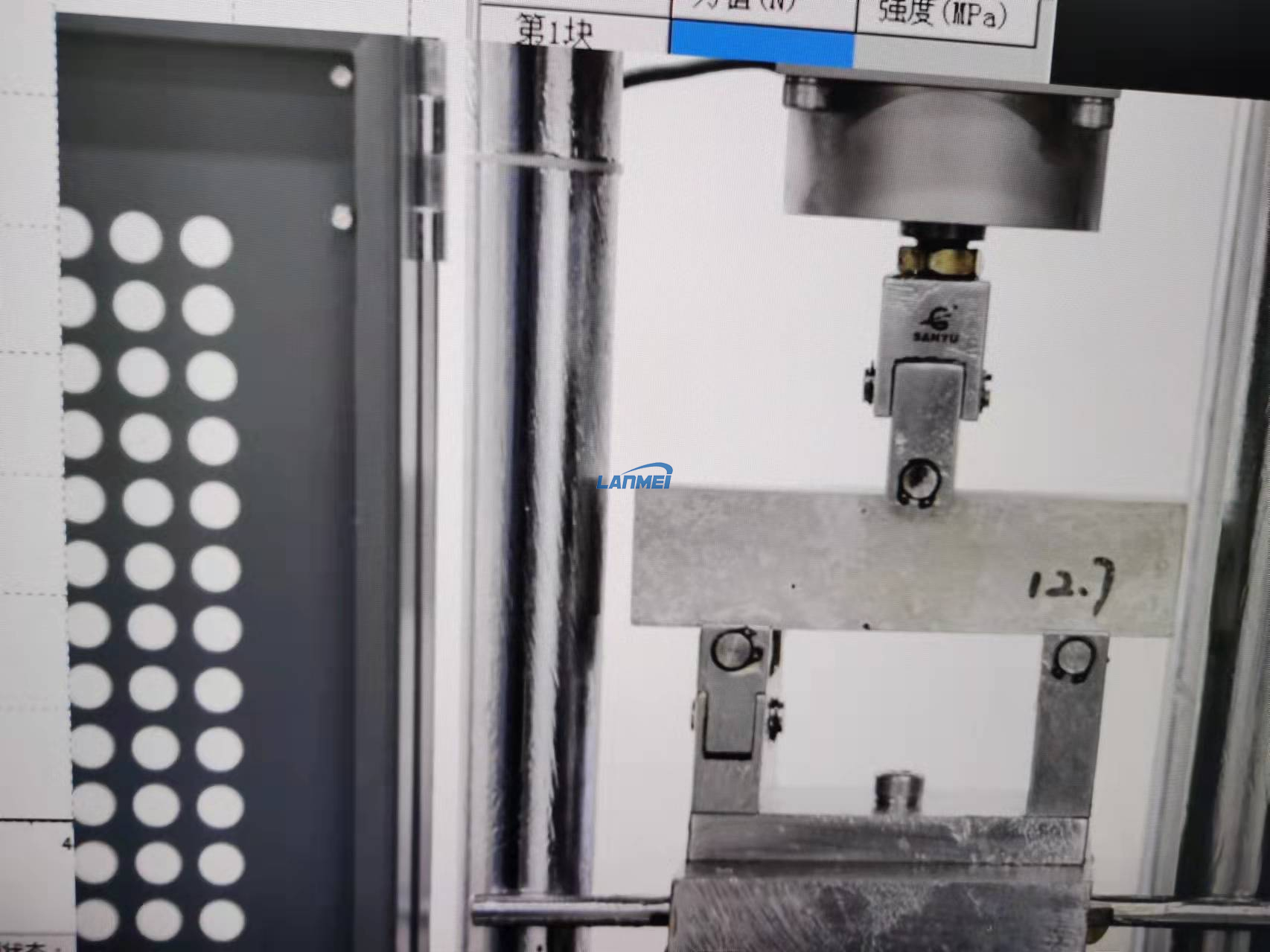

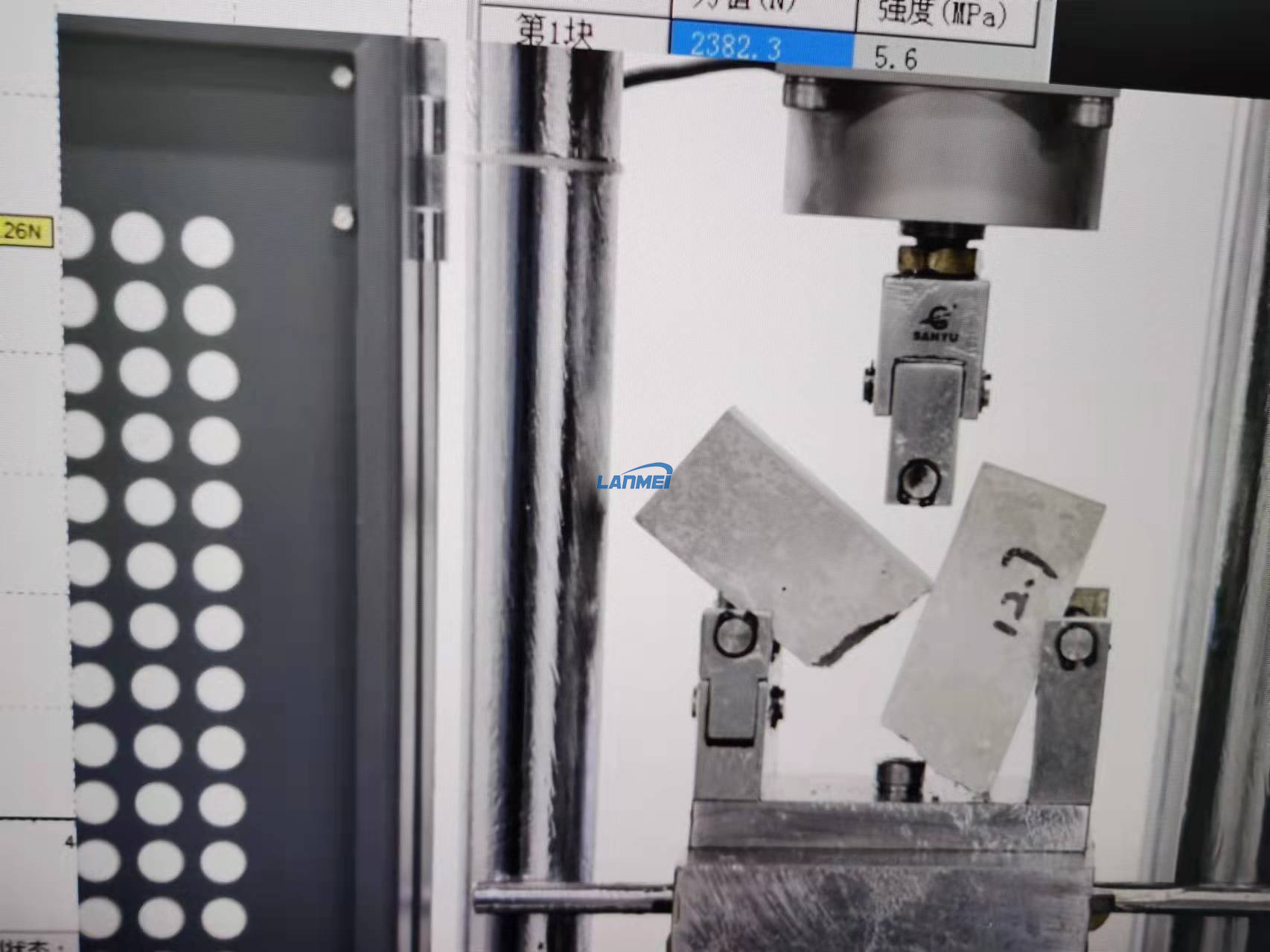

Isithombe sokuhlola isithombe:

Izithombe zokuhlola Flexiral:

-

I-mail

-

Ihathi

Ihathi

-

WhatsApp

WhatsApp

-

I-Facebook

-

I-YouTube

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur